Blog

What can the airTec technology from Homag for banding furniture edges do?

5.2.2020

The furniture industry is developing at a rapid pace and is constantly bringing new technologies to the market, which leads to more effective production and improved quality of the final products. Although our area of production is based on traditional furniture craftsmanship process, we also focus on continuous innovation and the use of the most state-of-the-art technologies. These include airTec from Homag, an advanced method of banding furniture edges, which we have been successfully working with since September 2019.

Homag is an industry leader.

Jointless banding of edges - technology of the future

The jointless method of banding edges, which represents the future in the field of edge banding machines, has been discussed among the professional public for a long period of time. Several months ago, we bought our own modern edge banding machine with airTec technology from the renowned manufacturer Homag. This company boasts more than 50 years of tradition in the production of edge banding machines and ranks among the three most important producers in the world. We can now offer our customers the unique opportunity to band the edges of tailored furniture using this method, which ensures the highest possible quality of banding and has other related advantages.

Banding edges without the use of glue

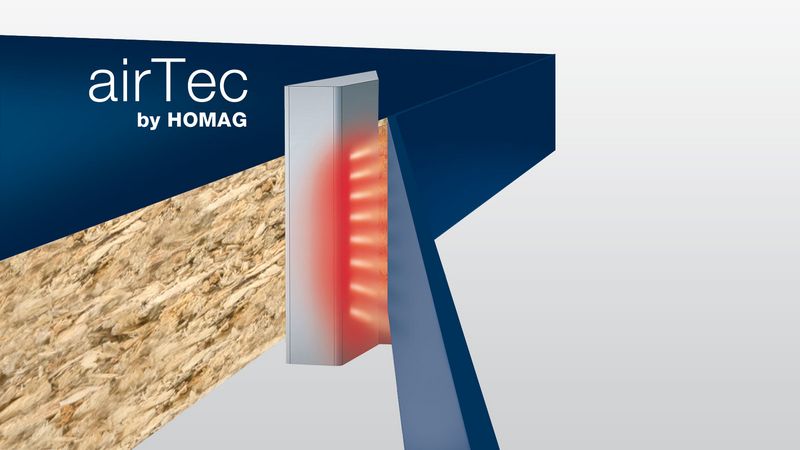

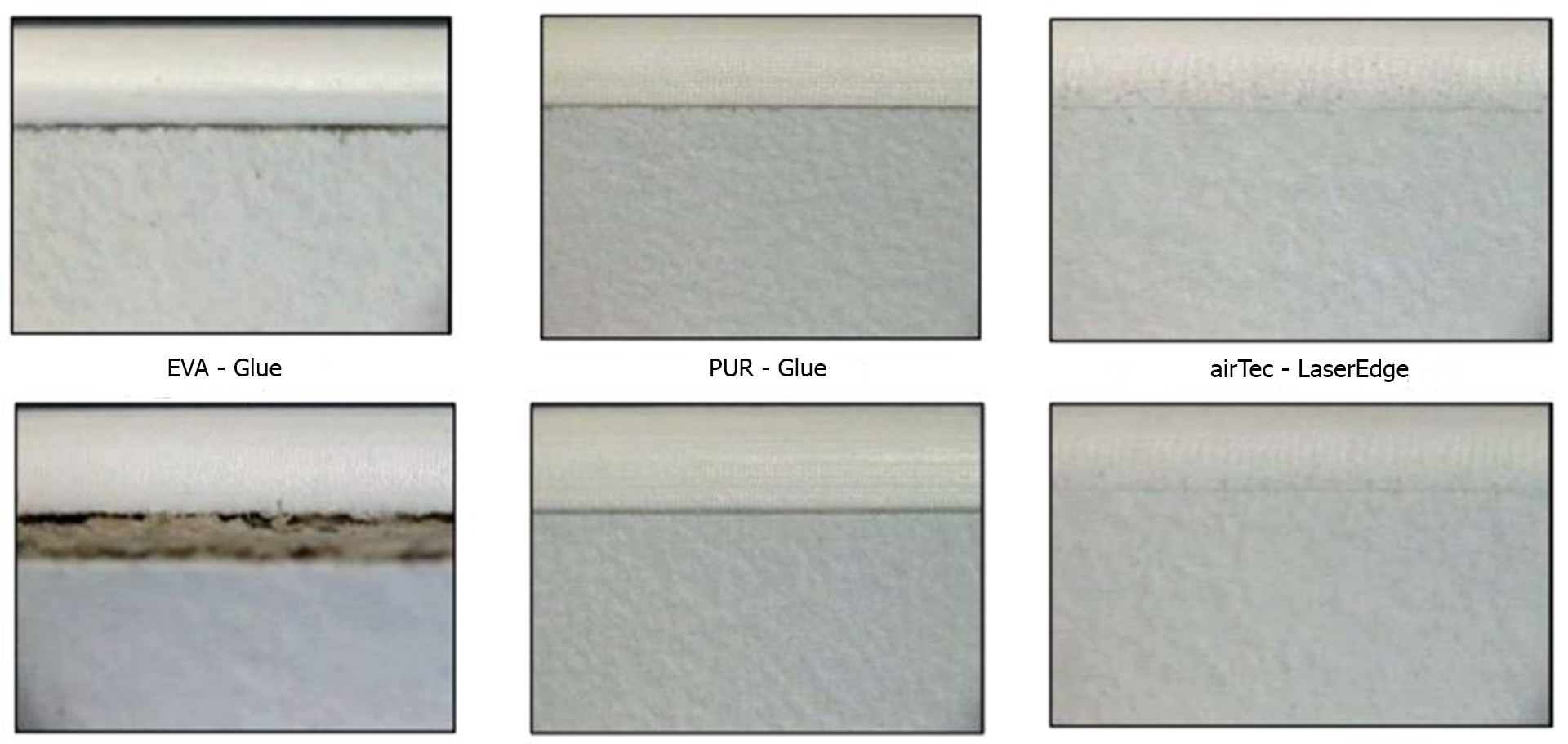

The airTec hot-air system uses a set of heating coils, which heats the air to a temperature of between 270 and 300°C. Although the airTec technology also uses classic adhesive application, it is primarily intended for the assembly of LaserEdge edges. These edges are composed of two layers - decorative and functional, which are melted directly onto the desired material. The edges are, therefore, banded without the use of glue. The result is a perfectly banded edge without visibly-glued joints, which would otherwise reduce the aesthetic value of the furniture.

Thanks to the airTec technology it is possible to produce a so-called “zero gap” and band edges using a laser.

The airTec system is ecological and hygienic

The advantage of the airTec system from Homag is its environmental-friendliness, which Profil Nábytek has long accentuated. Due to the fact that the edges can be banded without the use of glue, there are no chemicals released into the atmosphere or spreading of unpleasant odors. Of course, there is no other gradual release of pollutants into the air.

Another great advantage of this technology is that is also hygienic. The jointless edge banding system is certified for use in the production of furniture, for example in hospitals or ambulances.

Jointless edge banding can also withstand moisture

Furniture with LaserEdge edges excels not only in its eye-catching appearance and hygienic safety, but also in its properties. These include, for example, good resistance to high temperatures and humidity, which is much higher than conventional EVA adhesives. In addition, the edges for jointless banding can guarantee color matching with the board. This eliminates the need to match the color of the edges and the adhesive, which are not used in this banding process.

The configuration of the machine is individual and can always be adapted to the customer’s requirements.

Acquaint yourself with other cutting-edge technologies

We have long been focused on the continuous modernization of our production plant and the use of state-of-the-art machine tools to provide tailored furniture production at the highest possible level. That is why we routinely use, for example, a cutting center with a chaotic storage system, a CNC milling center with form banding and a BHX 500 continuous drilling center. In the future, we also plan to precure large-format gantry CNC machines intended for use under the most demanding conditions.

Do you need high-quality furniture for offices, healthcare facilities or atypical interiors? In all of these cases, we can provide tailored furniture using the latest technologies, including airTec edge banding. Contact us.